🔥 See other categories in this collection! 🔥

MAS Epoxies Deep Pour Epoxy Resin Kit - Crystal Clear, Slow Curing Epoxy Resin for Casting, River Tables, Encapsulating, Live Edge Slabs, Molds,

Availability & Shipping

Availability & Shipping

- Product availability: This is a US based website and some products may not be available outside the US.

- Shipping info: The majority of items have free shipping, but some products due to size or shipping location may have a shipping fee.

- Our Supporting Artisans who helped curate the products on this site will share commissions for purchases made through links in this post.

Transparency

Transparency

- Transparency: Unfortunately due to high levels of fraud committed on this shop our team has decided to only work with trusted suppliers to bring you the high quality items and fast shipping you've been used to from now on.

🔥 Newsletter 🔥

Sign up for exclusive offers, new items, and more.

Description

Description

Brand: MAS

Color: Clear

Features:

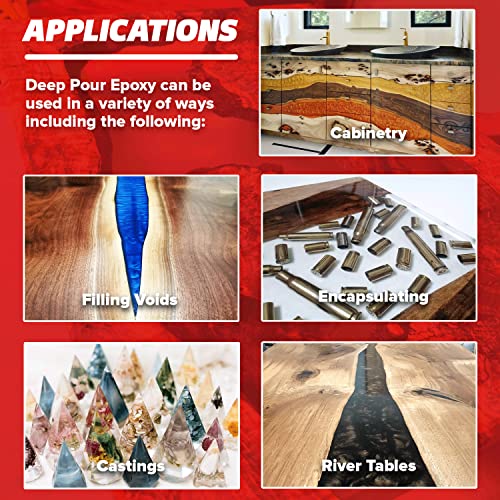

- DEEP POUR EPOXY RESIN AND HARDENER KITS for river tables, live-edge slabs, casting, deep resin molds, art, embedding, encapsulating and filling large voids and cracks in wood; cures to a 100% solid and is sandable and machinable once fully cured.

- CRYSTAL CLEAR EPOXY RESIN self-levels to creates a high-gloss, glass-like finish on prepared wood, concrete, stone, ceramic and metal surfaces; great for deep casting and molding projects to create unique sculptures, figurines, jewelry and more

- MAX CASTING THICKNESS UP TO 1" THICK PER POUR: Pour single layers of resin up to 1/2” thick for larger casting applications such as slab and river table pours, and up to 1" thick for smaller molds; for pours over 1” thick per layer, try MAS Epoxies Deep Pour X (sold separately)

- EASY TO USE, EASY TO TINT: Simple mix ratio of 3 parts epoxy resin to 1 part hardener, and extended working time make it easy to use. Pour clear or add color, tint mixed liquid epoxy with mica powder, translucent dyes, alcohol ink pigments and other epoxy-safe colorants

- LOW VOC, LOW ODOR RESIN IS AVAILABLE IN THREE SIZES: 1.3 Quart Kit (1 qt resin, 1/3 qt hardener), 1.3 Gallon Kit (1 gal resin, 1/3 gal hardener), 4 Gallon Kit (3 gal resin, 1 gal hardener) 100% made in the USA

Details: MAS Epoxies Deep Pour is a high quality deep pour epoxy system for DIY and professional hobbyists, artists, makers and woodworkers. This clear, high gloss, scratch-resistant low viscosity epoxy resin cures like glass, to let you create a unique piece of furniture, sculpture or art. Deep Pour is a clear epoxy resin that provides an extended working time that allows deeper pours per layer. Rather than 1:1 epoxy products that require a max casting thickness of 1/4” layer per pour. PLEASE NOTE: This is an advanced deep pour epoxy resin system. DO NOT use Deep Pour resin in working temperatures above 75°F. Please take into consideration the volume of epoxy you pour into a void. Pouring too much epoxy into a large area may result in shrinking, yellowing or cracking. Keeping the work area cool by adding a fan can help reduce the risk of the epoxy overheating. For best results, all materials and working conditions should be maintained at a constant 60°F-75°F. Epoxy is a temperature sensitive material. When cool, it’s thicker and sets slower. When warm, it’s thinner and sets faster. Working in a shop or with material above 75°F, Deep Pour may set too quickly and exotherm (become too hot) which could cause it to yellow, distort, shrink or crack. Max casting thickness can vary depending on a number of factors including shop temp, material temp, mixing quantity, mold material, project dimensions, etc. Larger slabs should be poured thinner than smaller castings to minimize exotherm. Every project is unique, but as a general guideline do not exceed 0.5” casting thickness for a full mixed 1.3 gallon kit, or 1” for a half mixed kit. Step pour multiple layers for thicker castings. When casting materials like wood, leaves, rocks and other substrates, make sure the material is dry and sealed. We recommend sealing any wood or porous surfaces prior to using Deep Pour Epoxy. Penetrating Epoxy Sealer works great for sealing the wood to reduce the risk of air bubbles and foam appearing while curing.

EAN: 0810395007030

Package Dimensions: 7.8 x 5.2 x 4.0 inches